INFRASTRUCTURE

Unit I

Location: Ahmedabad, India. Products manufactured:

Reactive Series Dyes

Capacity Installed:

Reactive Series Dyes : 1800 MTPA

Unit II

Location: Ahmedabad, India. Products manufactured:

Dyes Intermediates

Capacity Installed:

Dyes Intermediates : 4200MTPA

Unit III –Reactive Dyes, Drying & Packing

Location: Ahmedabad, India. Products manufactured:

- Reactive Dyes , Drying & Packing

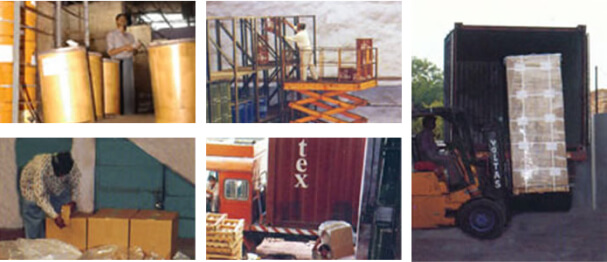

Standard packaging and on-time delivery are integral parts of the quality drive at ADPL. In fact, the company channelizes a good part of its industrial energy into post-production phases.

For smooth functioning the Packaging & Despatch Departments have been constructed in a separate area, with large storage capacities for crude materials inventory and packed materials. Blenders with high capacities enable faster standardization as per customer requirements, executed directly under the Quality Control Manager.

ADPL products feature a range of packing methods to suit divergent client requirements and usage patterns. Most of these products are available off-the-shelf, or are accessible through an efficient dealer network.

Unit IV –On going Unit Expansion

Location: Location: Saykha GIDC, Bharuch India:

Planned Products manufactured Dyes

Dyes Intermediates-

Proposed Capacity Installed

1800MTPA

Research & Development

ADPL R&D Cell functions on two clear exploratory guidelines:

Innovate and create new products or new versions of existing products, in response to market trends and demands.

Improve existing processes to achieve optimum cost-effectiveness for internal and external customers.

Over the years, ADPL has built a team of highly qualified professionals with vast experience in the science and technology of Dyes Synthesis, and driven by an objective of continuous technological improvement.

The R&D laboratory features equipment such as Mini Reactors with Stirrers, Pilot Reverse Osmosis System and Drying Units, to replicate mass production processes accurately.

In response to customer requirements, ADPL R&D team is now making a foray into the manufacture of low salt and echo-friendly dyes. Environment-friendly technologies and processes are being adopted by the company, with this specific objective.

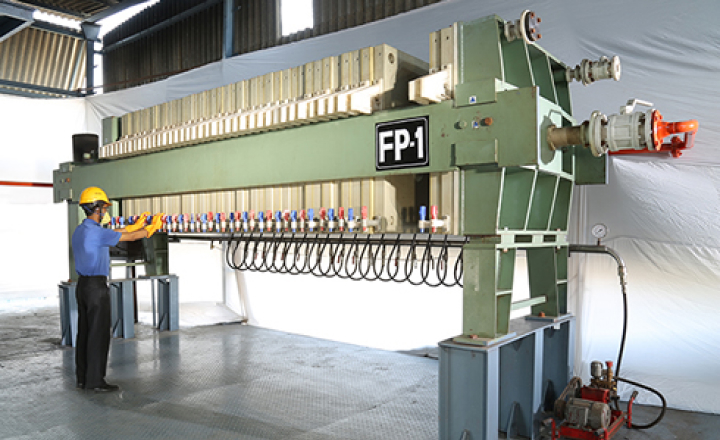

Pilot Plant

The R & D division is connected to a well-equipped Pilot Plant which enables the R & D technicians to conduct Plant-like production of their R & D experiments. The Pilot plant replicates actual plant-like reaction environment. Hence, it ensures a smooth transition of any new product from the R & D Lab scale to the plant scale for commercial production.

The Pilot Plant is equipped with

- H2 hydrogenator

- 50 – 200 ltrs. reactors

- 1 Sulfonator

- 1 Pressure Vessel (S.S.)

- Filter press

- Drying System

- Pilot Reverse Osmosis (R.O.)

The Pilot plant was designed with a view to develop new products as per customer’s requirements as well as for custom manufacturing of specialized products, which requires exhaustive sampling before starting commercial production in the plant.

Production

ADPL assimilated production technologies from the most reputed sources around the world. The company has renovated its plants as per a new generation lay-out, to optimize production output. It has streamlined its functions, to expedite processes.

The ADPL plant is equipped with high-capacity reactors and closed reactors capable of high pressure & temperature reactions. It features Spray Dryer units with very capacities, and Reverse Osmosis System producing Salt-Free Dyes.

Highly skilled technology experts and experienced technicians complement ADPL quality chain.